- #OPTICAL FIBER PREFORM MANUFACTURING TECHNOLOGIES PATENTS MANUAL#

- #OPTICAL FIBER PREFORM MANUFACTURING TECHNOLOGIES PATENTS TV#

The core portion of the optical fiber preform can be prepared by any known methods, for example, by Atmospheric Chemical Vapor Deposition (ACVD) method, wherein the soot is depositedġ0 during the deposition process step on the cylindrical member (also referred as target rod or mandrel) with a hollow glass handle intact, used for ease of handling the soot porous body so formed. The core portion comprises the core and a part of cladding of the fiber preform. The optical fiber preform is an enlarged image of optical fiber, which like the optical fiber comprises a central core portion and an outer cladding. In batch type manufacturing, the optical fiber is obtained by drawing optical fiberĥ preform. Manufacturing process, which in turn means that it is necessary to reduce the optical fiber preform and precursors manufacturing process time as much as possible. Reducing the manufacturing timeĬan enhance the production efficiency of the optical fiber preform and precursors Precursors thereof to be economical in order to support the increasing demand of opticalįiber and that too at low cost, meaning thereby, it is necessary to improve the productionģ0 efficiency of the optical fiber manufacturing process. It is desirable that the manufacturing process of the optical fiber preform and Any other geometric shape and profileĢ5 of the refractive index of the core is possible catering to a particular need. Generally, either the refractive index of the core is substantially uniform across its diameter (also called step index optical fiber) or the refractive index of the core has a maximum at the center and decrease in parabolic fashion near the periphery (also called graded index optical fiber). The refractive index of core is higher as compared with the refractive index of the cladding in order toĢ0 achieve light transmission inside the optical fiber, by the phenomena known as total internal reflection. Optical fiber comprise a core and a cladding surrounding the core.

#OPTICAL FIBER PREFORM MANUFACTURING TECHNOLOGIES PATENTS TV#

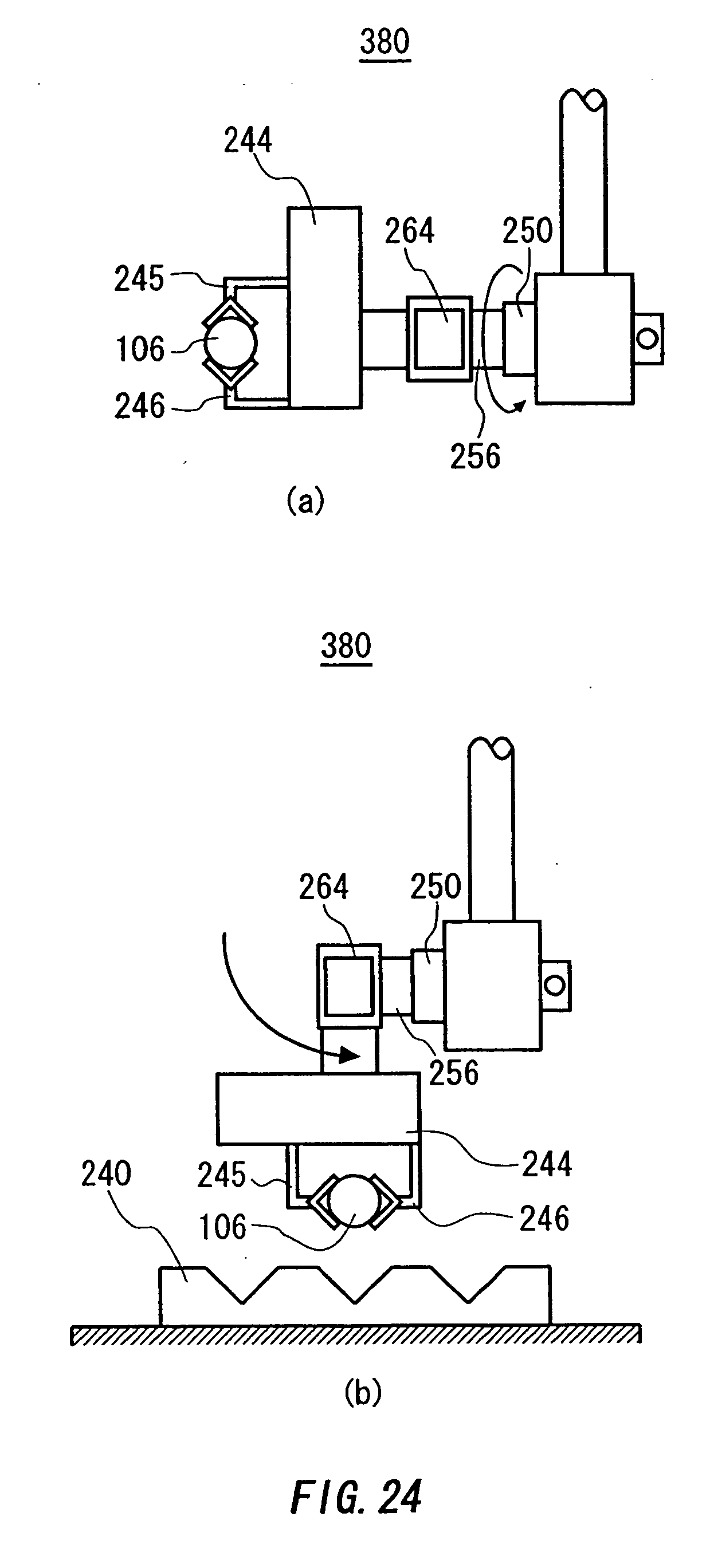

Of optical fibers in local loop telephone and cable TV service will increase in order toġ5 deliver greater amount of information in the form of data, audio, and video signals to There has been a momentous increase in usage of optical fibers. The role of Optical fibers has become significant in the field of communications. Thereof reducing overall manufacturing time and making the transportation of opticalįiber preform and precursors thereof simple and safe. Particularly, the present invention relates toĥ a novel mechanism for loading and holding hot optical fiber preform and precursors thereof, capable of loading and holding bulky optical fiber preform and precursors Optical fiber preform and precursors thereof. The present invention relates to a novel mechanism for loading and holding hot The following specification particularly describes and ascertains the nature of this invention and the manner in which it is to be performed:. Nationality : Indian (A Company Registered under Indian Companies Act)Īddress :Ğl, E2, E3, MIDC, Waluj, Aurangabad, INDIA - 431136, "A NOVEL MECHANISM FOR LOADING AND HOLDING HOT OPTICAL FIBER PREFORM AND PRECURSORS THEREOF."

#OPTICAL FIBER PREFORM MANUFACTURING TECHNOLOGIES PATENTS MANUAL#

The present invention solves the problem of holding hot optical fiber preform 5 and precursors thereof and reducing the manufacturing time of the optical fiber preform and precursors thereof, by about 15%, and thus the manufacturing cost of the optical fiber preform and precursors thereof, eliminating the need for cooling of the optical fiber preform and precursors thereof to room temperature, meaning thereby, the hot optical fiber preform and precursors thereof can be held and transferred safely and easily from 10 one stage to another without manual intervention.ĬOMPLETE SPECIFICATION (SEE SECTION 10 AND RULE 13) AN APPARATUS AND A METHOD FOR LOADING AND HOLDING HOT OPTICAL FIBER PREFORM AND PRECURSORS THEREOFĪ novel mechanism for holding hot optical fiber preform and precursors thereof is disclosed.

0 kommentar(er)

0 kommentar(er)