- #Xbar and r chart excel template manual

- #Xbar and r chart excel template software

- #Xbar and r chart excel template free

For the equation setup and calculation limits, please refer to the Gage R&R Link for equation and constant setup. We have done all the hard work for you, so just follow these simple steps. In this section, the excel setup from X Bar method for Gage R&R.

This template is exactly what you would create on your own, if only you had the time. Subgroup Reports This pane tabulates the values plotted on the control charts: Subgroup Reports All Subgroups X Excluded Beyond Limits Subgroup Size X-bar Range 1 5 1.51188 0.3679 2 5 1.49512 0. Pane Options The same options exist as for the X-Bar chart.

#Xbar and r chart excel template software

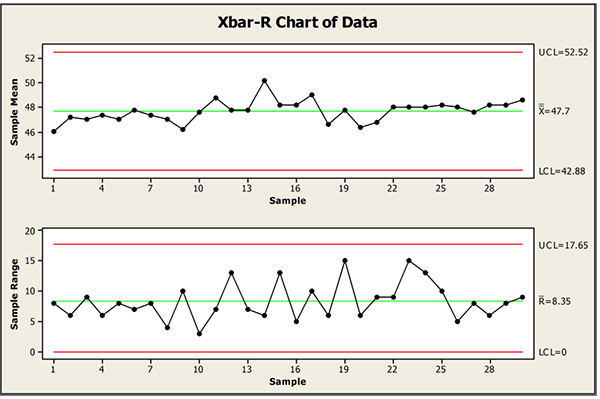

No expensive software to purchase, just a simple solution to your needs. The R chart for the sample data shows no unusual signals. The template is yours to edit and customize as you choose, or simply use it as is. Most out-of-control points identified on a Moving Range chart are usually easy to identify on the Individuals chart. This monitors the spread of the process over time. The first chart (Xbar chart) is a chart for subgroup. R chart: The range of the process over time from subgroups values. The second chart is the R chart, which displays subgroup ranges.

#Xbar and r chart excel template free

Control Chart Template - 5 Free Excel Documents Download. The control limits on the X bar consider the sample’s mean and center. Remarks: In the X-bar & R tax chart, the numerical of observations per samples (n) can be. The template does not include an MR chart. X bar chart: The mean or average change in a process over time from subgroup values. It was developed for engineers and others who want to save time in setting up such templates

#Xbar and r chart excel template manual

It is a template of a form to be used to enter process data so manual process charting can take place in time. Note that no calculations are performed by this spreadsheet. The intent of the form is for the user to modify the scales on the left, then print it out for manual control charting. This X-bar and R chart has room for up to 5 samples.

These variable charts, used as a pair, plot the mean and range of subgroups taken from your process. The first step is to determine your process's mean moving range, mean (mR). Use the sequential deviation to calculate the control limits. Determine the mean (mR) Convert the mean (mR) to a sequential deviation. Use this Microsoft Excel template for implementing SPC by hand with these Individuals and X-bar and R charts (two worksheets). There are 3 steps to determining XmR Control Limits. Look for special or assignable causes and adjust the process as necessary to maintain a stable and in control process.įormulas from 2002, Manual on presentation of data and control chart analysis, ASTM International, West Conshohocken, PA.Downloadable Excel template for use today Looking for Xbar And R Chart Powerpoint Slide Rules PowerPoint templates Find predesigned PPT templates, presentation slides graphics, images and designs. With the control limits in place, gather samples, and plot the data. Once you decide to monitor a process and after you determine using an $- \bar$$ 8. Plot the data (both the averages and the ranges). Calculate the average and range for each subgroup. Collect your data (take a set of readings at each specified interval of time). Determine an appropriate subgroup size and sampling plan.

X-Bar and R Chart Subgroup Size of 2 to 9 Samples. Metals Engineering and Product Reliability Here are the most common variable-data control charts 1.Product Development and Process Improvement.Rooted in Reliability: The Plant Performance Podcast.

0 kommentar(er)

0 kommentar(er)